Electric motors rely on several core components to convert electrical energy into motion, with brushes playing a critical role in specific motor types. In the context of electric motor manufacturing, understanding the purpose and mechanics of brushes is essential for selecting the right motor for an application. For an electric motor manufacturer like Santroll, precision in these components directly influences performance and longevity.

Establishing the Electrical Connection

Brushes are typically made of carbon or graphite and are held in place by a spring-loaded mechanism. Their primary function is to conduct electrical current between the stationary part of the motor (the stator) and the rotating part (the rotor). They maintain sliding contact with the commutator, a segmented copper sleeve on the rotor shaft. This continuous connection is what enables the rotation to persist.

Facilitating the Commutation Process

The commutator and brushes work in tandem to manage the direction of current flow in the rotor’s windings. As the rotor spins, the brushes contact different segments of the commutator. This action systematically reverses the current in the windings at the correct moment, which ensures that the magnetic forces produce a continuous, unidirectional torque. Without this commutation process, the motor would not be able to sustain its rotation.

Considering Maintenance and Material Science

Due to their sliding contact, brushes are a consumable part and experience gradual wear over time. The materials used in their construction are chosen for a balance of electrical conductivity, lubricity, and resistance to arcing. The expertise of an electric motor manufacturer is evident in selecting brush materials that minimize electrical noise, reduce sparking, and extend service intervals, a key consideration in Santroll’s electric motor manufacturing process.

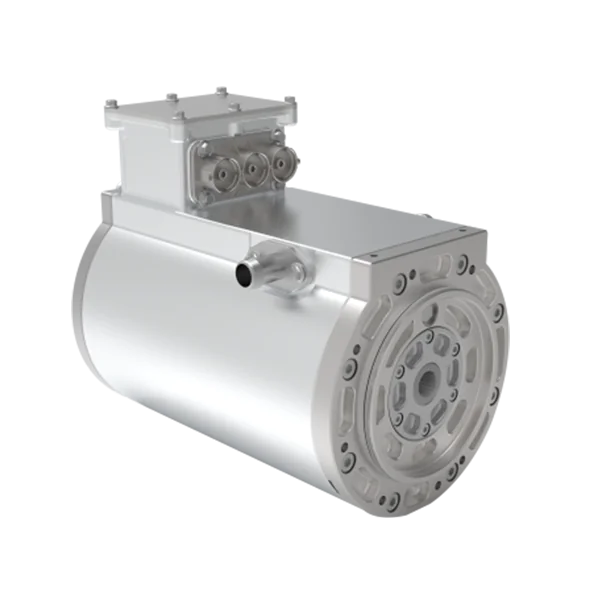

The design and material quality of brushes are therefore integral to the reliability of brushed motors. While brushless designs exist for certain applications, brushed motors remain vital where their specific torque characteristics and cost-effectiveness are advantageous. The engineering focus at Santroll, as a dedicated electric motor manufacturer, ensures that even these fundamental components are optimized for durability and consistent performance in industrial settings.